In recent years, the world has witnessed a growing concern for the environment and sustainable practices. As industries strive to reduce their ecological footprint, one area that has shown immense promise is the intersection of green technology and 3D printing. This innovative combination has the potential to revolutionize manufacturing and prototyping processes, paving the way for eco-friendly practices that benefit both businesses and the planet. In this blog, we'll explore the remarkable advancements in green technology and 3D printing, and how they are transforming the landscape of modern manufacturing.

Green technology, also known as clean technology or eco-friendly technology, refers to a range of innovations that aim to minimize the environmental impact of industrial processes. From renewable energy sources to sustainable materials, this emerging field focuses on reducing waste, conserving resources, and lowering emissions. When integrated into manufacturing and prototyping, green technology presents an opportunity to revolutionize traditional practices and create a more sustainable future.

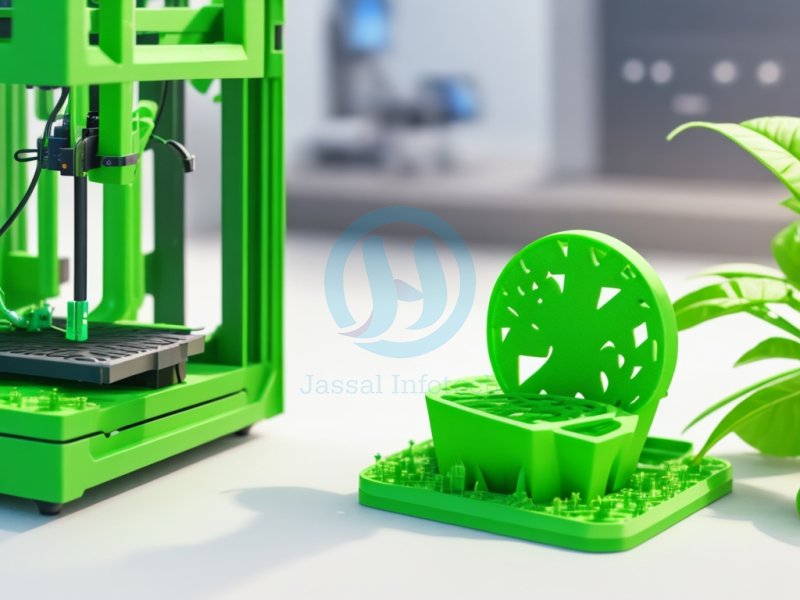

3D printing, or additive manufacturing, is a groundbreaking technology that has gained significant attention in various industries. Unlike conventional subtractive methods, which involve cutting and shaping materials, 3D printing builds objects layer by layer using raw materials like bioplastics, recycled plastic, or even organic materials. This process drastically reduces waste generation and energy consumption while enabling the creation of complex designs that were previously impossible with traditional techniques.

The amalgamation of green technology with 3D printing is a match made in eco-conscious heaven. By utilizing eco-friendly materials and energy-efficient processes, businesses can align their manufacturing and prototyping operations with sustainability goals. Some exciting developments in this area include:

One of the cornerstones of green technology and 3D printing collaboration is the advancement of the circular economy model. Traditional linear manufacturing systems follow a "take-make-dispose" approach, leading to the accumulation of waste in landfills. However, 3D printing allows for localized and on-demand production, reducing the need for mass production and excess inventory. Additionally, products can be easily repaired or upgraded, extending their lifecycle and minimizing waste.

The marriage of green technology and 3D printing holds the potential to transform the manufacturing and prototyping landscape into a sustainable and eco-friendly realm. With reduced waste, energy efficiency, and the advancement of circular economy principles, this combination offers a path to responsible and environmentally conscious practices. Embracing these innovations not only benefits businesses through cost savings and improved efficiency but also contributes to the preservation of our planet for future generations. As industries continue to adopt and refine green 3D printing practices, we can look forward to a brighter, greener future.

Share This News